Why Use an Active Optical Cable?

Active optical cable (AOC) is a high-performance communication cable used for short-range multi-lane communication and interconnected applications.

What is an Active Optical Cable (AOC)?

An Active Optical Cable transforms the data signal into a laser light, which is communicated over an optical fiber. The conversion of electronic data is done by an optical transceiver connector. This allows for the fiber to disconnect from the transceiver. At the transceiver’s end, Active Optical Cables bond the fiber connection, which in turn creates a cable assembly similar to a DAC cable.

Active optical cable have four functional parts.

1. High-density QSFP+ connector allows for the cable to be plugged into a router or switch.

2. 4- Channel full duplex active optical cable transceiver is embedded inside the shell and is responsible for electrical- optical conversions, making AOCs a lower cost solution in comparison to other transceivers.

3. MPO optical connector is a permanent attachment to the shell and fiber, protecting the interface from the end users (consumers) and environmental contamination.

4. Flexible ribbon optical fiber cable

Advantages of Active Optical Cables

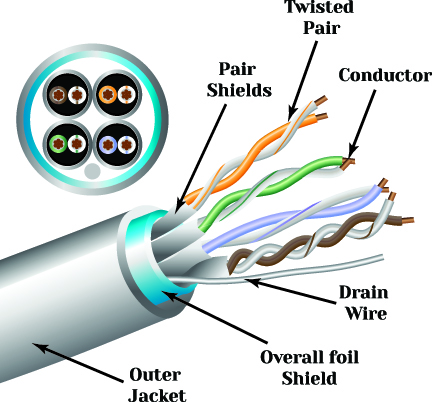

Active optical cable assemblies offer several potential advantages. In comparison to heavy copper cables, AOCs are lighter in weight and thinner. Therefore, they do not suffer from the length restrictions of copper cables. AOCs have longer reaching potential. Additionally, to address bandwidth issues, copper cables become bulkier and harder to manage and these cables risk more power delivery issues.

Therefore, the bulkiness and weight of copper cables make a terribly inelegant system communication solution. Copper cables may be a somewhat feasible solution for small data center clusters. However, for large clusters, the link distance and the actual layout of the cluster makes it physically challenging to manage and operate. Overall, copper cables make for a messy and complicated data center design solution. In addition, due to the nature of electrical signals, electromagnetic interference (EMI) limits both the performance and overall reliability of copper.

Active Optical Cables were initially invented to replace this limited copper technology across data centers. AOCs are far superior in performance and their advantages are undeniable. Some super computers have completely shifted from using coper cables to AOCs. The electrical to optical conversion improves the speed and increases the distance performance of its predecessors, while still remaining compatible with standard electronic devices.

Active Optical Cable Final Thoughts

AOCs must adhere to the IEEE, IBTA and SFF standards. Since the optics are contained inside the cable, AOCs have freedom from industry standards for electrical, mechanical and thermal requirements, eliminating costly optical testing. In addition, the optics location gives AOC designers freedom to find consumers low cost materials and transceiver designs. Compared to copper cables, this makes AOCs a much more cost effective solution. In fact, a TMC active optical cable is currently one of the lowest priced optical interconnect available. Generally, they are about half the price of costly optical transceivers. Furthermore, if the network equipment utilized is properly designed, reconfiguration of AOCs are quite simple and easy. Also, AOCs are lightweight in comparison to its predecessors, making data centers physically easier to manage.

Summary of AOC Advantages

The main advantages of using AOCs over other communication cables solutions are:

– Improved performance

– Lighter weight

– Reduced bulkiness: Thinner and longer reach

– Higher bandwidth

– Immune to EMI

– Improved flexibility

– Lower power consumption

– Low interconnection loss

– Lower Bit Error Rate (BER)