Why Should You Use Custom-Length SAS And SlimSAS Cables In High Speed Systems

In high speed storage systems, cable length is not a cosmetic detail. At SAS 4.0 and PCIe Gen 4 or Gen 5 speeds, cable length directly affects signal integrity, airflow, mechanical reliability, and long term system stability. Custom-length SAS and SlimSAS cables allow system designers to optimize the physical channel instead of compromising around generic off the shelf lengths.

Minimizing Signal Loss at High Data Rates

As signaling speeds increase, insertion loss becomes one of the most limiting factors in the channel. Every additional centimeter of copper adds attenuation and reduces signal margin.

Custom-length cables allow runs to be kept as short as possible while still supporting clean routing. This preserves eye opening at the receiver and reduces the risk of links training at lower speeds or becoming unstable under load. In PCIe Gen 4 and Gen 5 systems, this margin can be the difference between a reliable deployment and intermittent errors.

Improving Signal Integrity Consistency

Excess cable length often results in tight coils, sharp bends, or uneven routing near connectors. These conditions can distort impedance and increase reflections.

A cable built to the exact required length allows smooth, gradual routing that maintains consistent geometry along the entire run. This improves impedance control and reduces jitter, crosstalk, and return loss, all of which are critical at higher frequencies.

Reducing Mechanical Stress on Connectors and PCBs

Cables that are too long or too short frequently place unintended strain on connectors. Excess slack can pull sideways on ports when bundled, while short cables may tug directly on the connector or card.

Custom-length assemblies are designed to fit the chassis layout precisely, allowing proper strain relief and reducing mechanical load on connectors, solder joints, and PCB pads. This increases connector lifespan and lowers the risk of intermittent faults caused by mechanical fatigue.

Enhancing Airflow and Thermal Performance

Dense servers and storage systems rely on controlled airflow to maintain stable operating temperatures. Excess cabling can obstruct airflow paths, especially in 1U and 2U chassis.

Custom-length cables reduce clutter by eliminating unnecessary slack. Cleaner routing along chassis walls and defined cable paths helps maintain airflow efficiency and reduces hotspots around controllers, drives, and switches.

Supporting Cleaner Cable Management

Off the shelf cable lengths force installers to adapt routing around the cable rather than designing routing intentionally. This often leads to tangled bundles, overlapping runs, and difficult service access.

Custom-length SAS and SlimSAS cables support predictable, repeatable layouts. This improves serviceability, simplifies upgrades, and reduces the risk of disturbing adjacent connections during maintenance.

Maximizing Usable Space in Compact Builds

High density systems leave little margin for wasted space. Extra cable length can block bays, interfere with trays, or limit expansion options.

Custom cables allow designers to fully utilize available space without compromising routing discipline. This is especially important in systems with dense backplanes, multiple controllers, or mixed protocol storage configurations.

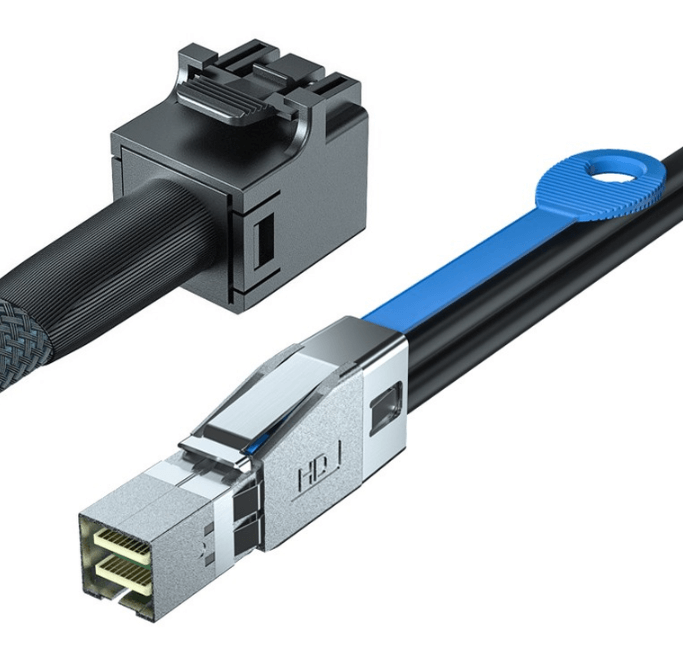

Enabling Precise Connector Orientation and Breakout Design

Custom assemblies are not limited to length alone. Connector orientation, such as straight versus right angle, and breakout geometry can be tailored to the system layout.

This allows cables to exit ports in the optimal direction, reducing bend stress and improving routing efficiency. For SlimSAS breakouts, precise length matching across branches helps maintain consistent signal timing and cleaner installation.

Reducing Troubleshooting and Long Term Risk

Many intermittent signal integrity issues trace back to marginal physical channels rather than controllers or drives. Overlength cabling consumes loss budget unnecessarily and reduces tolerance to temperature and load variation.

Custom-length cables provide additional margin that reduces the likelihood of hard to diagnose failures appearing later in production or field deployments.

When Custom-Length Cables Matter Most

Custom-length SAS and SlimSAS cables are especially beneficial in:

-

PCIe Gen 4 and Gen 5 storage systems

-

SAS 4.0 backplanes and expanders

-

High density 1U and 2U servers

-

NVMe heavy storage platforms

-

Systems with strict airflow and thermal requirements

In these environments, physical optimization directly impacts system reliability.

FAQ (Frequently Asked Questions)

Are custom-length cables only useful for very high speeds?

They provide the most benefit at higher speeds, but improved routing and reduced strain help at any data rate.

Do custom cables cost more than standard lengths?

They may have a higher unit cost, but they often reduce integration time and long term failure risk.

Can custom-length cables be reused in future systems?

They are best suited for a specific layout, but careful planning can allow reuse within similar platforms.

Is length the only customization option?

No. Connector orientation, breakout configuration, labeling, and shielding can also be specified.