What Is IPC/WHMA-A-620 And Why Is It Critical For Cable Assembly Quality

IPC/WHMA-A-620 is the industry standard that defines the acceptability of cable and wire harness assemblies. It establishes clear, measurable workmanship criteria for how cables are prepared, terminated, insulated, and finished. In environments where reliability, electrical performance, and mechanical durability matter, this standard provides a common quality baseline that manufacturers, engineers, and customers can trust.

What IPC/WHMA-A-620 is

IPC/WHMA-A-620 is a joint standard developed by IPC and the Wire Harness Manufacturers Association. Unlike design specifications, it focuses specifically on how cable and wire harness assemblies must be built and inspected.

The standard defines visual, mechanical, and electrical acceptance requirements for completed assemblies. It does not prescribe how to design a cable. Instead, it ensures that whatever design is specified is executed with consistent workmanship and verified quality.

Scope of the Standard

IPC/WHMA-A-620 covers a wide range of assembly processes, including:

-

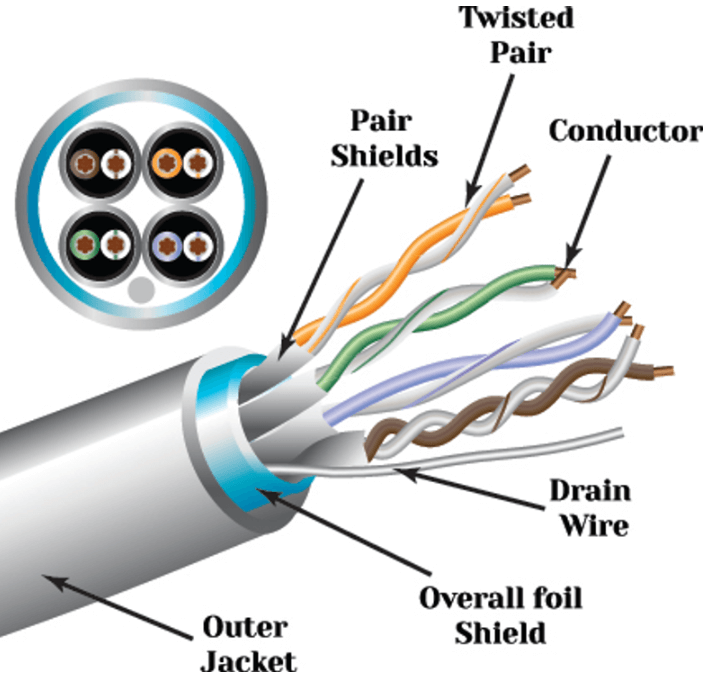

Conductor stripping and preparation

-

Crimped and soldered terminations

-

Connector and contact installation

-

Shield termination and grounding

-

Strain relief implementation

-

Insulation support and protection

-

Cable bundling, lacing, and sleeving

Each requirement includes clearly defined accept, process indicator, and defect conditions. This eliminates subjective interpretation during inspection and ensures uniform quality across production runs.

Why Workmanship Matters in Cable Assemblies

Cable assemblies are mechanical and electrical systems. Poor workmanship can introduce high resistance joints, intermittent connections, impedance discontinuities, or premature mechanical failure.

In high speed and high density applications, even small assembly defects can cause signal degradation, electromagnetic interference, or reduced reliability. IPC/WHMA-A-620 addresses these risks by enforcing disciplined assembly practices that preserve both electrical performance and mechanical integrity.

IPC-620 Classes and Their Significance

The standard defines three performance classes based on end use requirements:

Class 1 applies to general electronic products where basic function is sufficient.

Class 2 applies to dedicated service products where extended life and consistent performance are expected.

Class 3 applies to high performance or harsh environment products where failure is not acceptable. These assemblies require the tightest tolerances, highest workmanship standards, and strict defect criteria.

Selecting the appropriate class ensures that assembly quality aligns with the operational demands of the application.

Importance for High Speed and Precision Cabling

Modern cable assemblies often carry high frequency signals across tightly controlled impedance paths. Variations in crimp geometry, shield termination, or insulation placement can disrupt signal integrity.

IPC/WHMA-A-620 ensures that assembly practices support electrical consistency. This is especially critical for interfaces that operate at high data rates or require precise grounding and shielding performance.

Consistency and Repeatability in Manufacturing

One of the most important benefits of IPC/WHMA-A-620 is manufacturing repeatability. The standard requires documented processes, trained operators, and defined inspection criteria.

This reduces variation between builds, minimizes rework, and improves long term reliability. For customers, it means that each cable assembly performs consistently regardless of production volume or batch timing.

Risk Reduction and Traceability

Adherence to IPC/WHMA-A-620 lowers operational risk by preventing common assembly defects before they reach the field. It also supports traceability by aligning inspection records, workmanship criteria, and corrective actions under a recognized framework.

This is especially important in regulated industries or mission critical systems where failure analysis and root cause tracking are required.

When IPC/WHMA-A-620 Should be Required

IPC/WHMA-A-620 compliance is most valuable in the following scenarios:

-

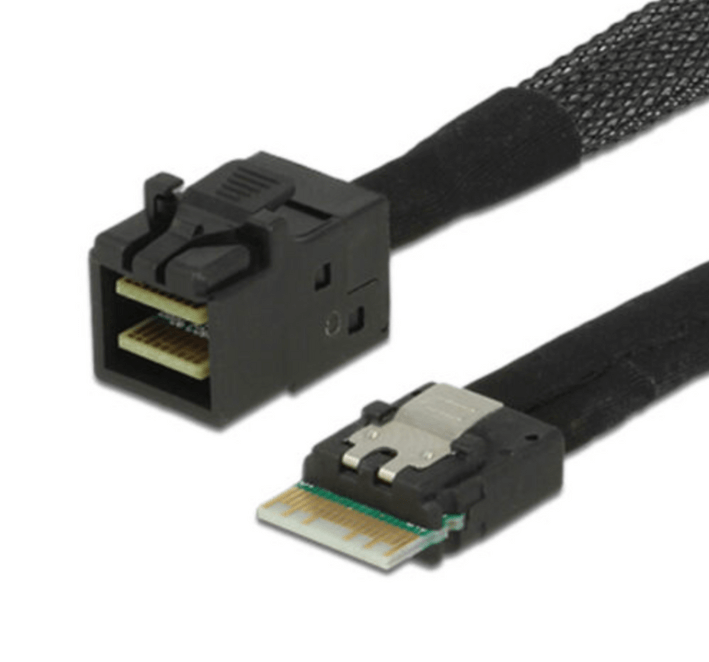

Enterprise and data center infrastructure

-

Aerospace, defense, and transportation systems

-

Medical and laboratory equipment

-

Industrial automation and control systems

-

High speed or high reliability interconnects

In these environments, workmanship quality directly affects system performance and uptime.

FAQ (Frequently Asked Questions)

Is IPC/WHMA-A-620 a design standard?

No. It defines workmanship and acceptability, not electrical or mechanical design.

Does IPC-620 certification apply to companies or individuals?

It applies to both. Organizations follow the standard, and individual operators and inspectors can be trained and certified.

Is IPC-620 required by regulation?

Not universally, but it is often contractually required in high reliability industries.

Does IPC-620 guarantee zero defects?

No, but it significantly reduces defect rates by enforcing consistent, verified assembly practices.