How Should Data Storage Infrastructure Prepare For PCIe Gen 5.0?

PCIe Gen 5.0 doubles per lane throughput to 32 GT per second, tightening electrical margins across the entire data path. Preparing storage infrastructure for this transition requires coordinated planning across cabling, connectors, routing discipline, and validation practices. Organizations that treat Gen 5 readiness as a system level effort can adopt new hardware with fewer integration risks and less rework.

Understand The Impact of Higher Signaling Rates

At Gen 5 speeds, attenuation, jitter, and crosstalk rise sharply. Channels that were stable at Gen 4 may fail to train or become intermittent at Gen 5 without changes to the physical layer. This affects not only drives and controllers but also connectors, cables, PCB traces, and routing topology.

Preparation starts with acknowledging that Gen 5 is not a drop in upgrade. Loss budgets are tighter, allowable lengths are shorter, and tolerances are stricter across all components.

Select Connectors and Interconnects Designed for Gen 5

Connector choice becomes more critical as frequencies increase. Interfaces designed with high frequency performance in mind provide better impedance control and lower transition loss. Internal connector families that support compact layouts and controlled impedance are preferred for dense backplanes and NVMe designs.

Avoid assuming backward compatible connectors will automatically support Gen 5. Verify that the connector ecosystem is validated at 32 GT per second and supported by silicon vendors.

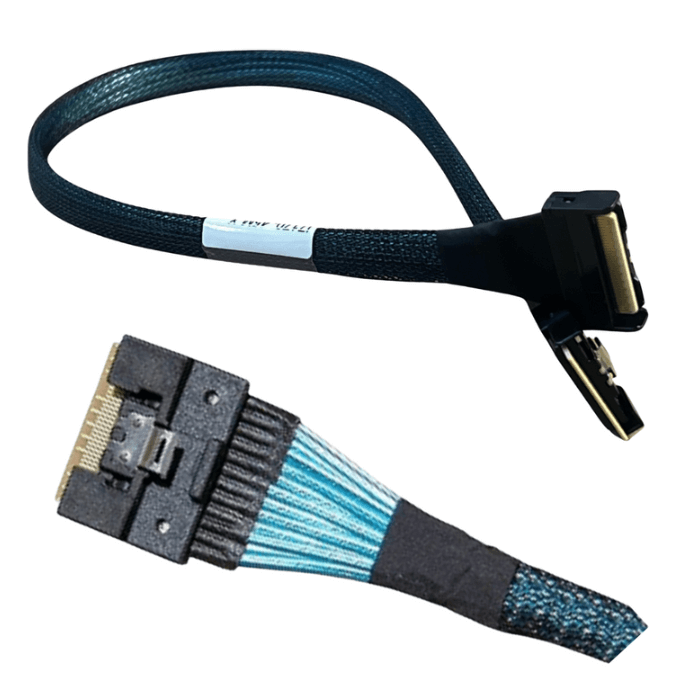

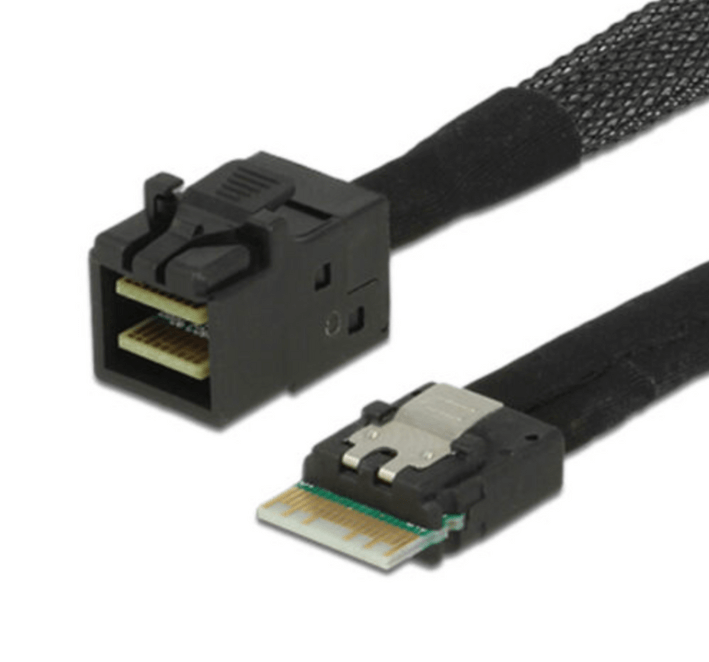

Upgrade Cabling to Gen 5 Capable Assemblies

Cables must be explicitly rated and tested for Gen 5 performance. Key characteristics include low insertion loss materials, tight impedance control, robust shielding, and precise termination.

Keep copper cable lengths as short as practical. Excess length consumes loss budget and increases susceptibility to noise. Where distances cannot be shortened, evaluate active solutions that maintain signal integrity over longer runs.

Reevaluate Lane Density and Topology

Gen 5 platforms often aggregate more bandwidth per connector, which can reduce the number of ports but increase per port criticality. Review lane mapping and aggregation to ensure the topology aligns with performance goals.

High density lane groupings demand careful attention to crosstalk and spacing. Designs that minimize connector hops and avoid unnecessary branches are more likely to pass Gen 5 requirements.

Tighten Routing and Mechanical Discipline

Mechanical handling directly affects electrical performance at Gen 5. Tight bends, strain near connectors, and routing near noise sources can degrade links.

Adopt routing practices that emphasize gentle curves, clear separation from power paths, and consistent strain relief. Cable management should support airflow and serviceability without compressing or deforming cables.

Plan for Signal Integrity Validation

Gen 5 readiness requires validation beyond basic connectivity checks. Incorporate signal integrity testing into deployment plans, including eye measurements at speed and link margin assessment where available.

Validation should reflect real operating conditions, including temperature and load. This reduces the risk of marginal links that pass initial testing but fail in production.

Consider Optical Options for Reach and Flexibility

As Gen 5 pushes copper to its practical limits, optical interconnects become increasingly relevant. For longer internal runs, inter rack links, or high bandwidth switch fabrics, optical solutions can provide stable performance with less sensitivity to distance and EMI.

Evaluate where optical links add value rather than defaulting to copper for all connections.

Align Infrastructure Refresh Cycles

Cabling and backplanes often outlive compute and storage devices. Aligning infrastructure upgrades with Gen 5 capable components reduces the likelihood of repeated refreshes.

Even if current deployments operate at Gen 4, selecting Gen 5 capable interconnects where feasible preserves flexibility for near term upgrades.

Update Operational and Procurement Standards

Preparation is not only technical. Update internal standards to require Gen 5 validation, proper documentation of cable specs, and clear acceptance criteria.

Procurement teams should be equipped to verify connector standards, protocol wiring, speed ratings, and test coverage to avoid incompatible purchases.

Common Preparation Scenarios

Gen 5 planning is especially important in:

-

NVMe intensive storage platforms

-

PCIe switch based architectures

-

AI and accelerator dense systems

-

High density 1U and 2U servers

-

Environments with frequent hardware refresh cycles

In these cases, early preparation minimizes disruption.

FAQ (Frequently Asked Questions)

Can Gen 4 cabling be reused for Gen 5 upgrades?

Sometimes, but only if length, construction, and validation support Gen 5 requirements.

Is Gen 5 preparation only about cables?

No. It involves connectors, routing, PCB design, and system validation as well.

When should optical links be considered?

When copper length limits or EMI constraints threaten Gen 5 stability.

Does Gen 5 require redesigning existing racks?

Not always, but routing discipline and cable management may need adjustment.