Why Are SlimSAS Cables Becoming Standard In High Density Server Designs?

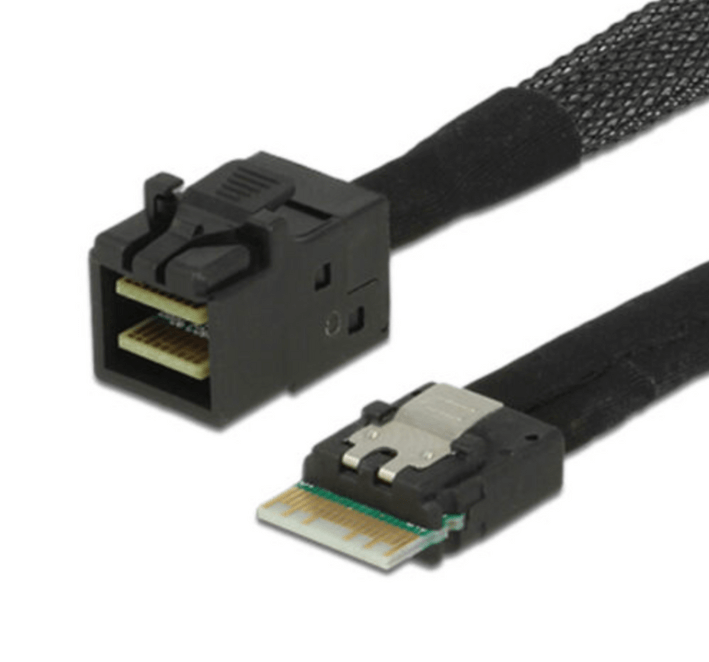

SlimSAS cables are increasingly adopted in high density server designs because they address the combined challenges of bandwidth growth, space constraints, and signal integrity. As servers integrate more storage devices, PCIe lanes, and accelerators within fixed chassis dimensions, traditional internal cabling becomes a limiting factor. SlimSAS provides a compact, high performance interface that supports modern storage and compute requirements without increasing physical complexity.

Density Challenges in Modern Server Architectures

High density servers are designed to maximize compute and storage capacity per rack unit. This requires more internal connections between CPUs, controllers, backplanes, and drives, all within a constrained mechanical envelope. Legacy internal SAS and PCIe cabling systems consume significant board edge space and require thicker cable bundles that restrict routing options.

SlimSAS reduces connector footprint and cable bulk, allowing designers to place more ports on a single board and route cables more efficiently. This directly supports higher device counts and more flexible internal layouts.

High Bandwidth Requirements and Lane Consolidation

Modern storage systems rely on fast solid state media and wide PCIe links to deliver required performance. SlimSAS supports high per lane data rates and multi lane configurations, enabling large amounts of bandwidth through a single compact connector.

By consolidating multiple lanes into a smaller interface, SlimSAS reduces the number of connectors required to achieve a given throughput level. This simplifies designs and improves scalability as performance demands increase.

Signal Integrity in Tight Layouts

As data rates increase, maintaining signal quality becomes more difficult, especially when connectors are placed close together. SlimSAS connectors and cable assemblies are engineered with controlled impedance, optimized differential pair spacing, and effective shielding to minimize crosstalk and reflections.

These electrical characteristics allow reliable operation in dense PCB layouts where spacing between ports is limited. This makes SlimSAS well suited for next generation servers that operate at higher speeds without sacrificing stability.

Mechanical and Thermal Advantages

SlimSAS cables are thinner and more flexible than many legacy multi lane assemblies. This improves internal airflow, which is critical in high density systems where thermal margins are tight. Better airflow supports consistent component temperatures and reduces the need for aggressive cooling strategies.

Reduced cable stiffness also lowers mechanical stress on connectors and solder joints, improving long term reliability in systems that may experience vibration or frequent servicing.

Protocol Flexibility for Mixed Workloads

SlimSAS supports multiple protocols, including SAS, SATA, and PCIe, depending on system configuration. This flexibility allows a single physical interface to be used across different storage technologies.

In high density designs that must support a mix of NVMe, SAS, and SATA devices, SlimSAS simplifies platform design and reduces the number of unique cable types required. This standardization benefits both system builders and operators.

Support for Modular and Scalable Designs

Modern server architectures increasingly favor modular components such as PCIe switches, storage backplanes, and composable infrastructure. SlimSAS aligns well with these approaches by enabling short reach, high bandwidth internal links that can be easily scaled or reconfigured.

Designers can add or reallocate lanes without redesigning the entire cabling system, which supports faster platform development and longer product lifecycles.

Typical Use Cases Driving Adoption

SlimSAS cables are commonly used in the following environments:

-

High density NVMe storage servers

-

Enterprise and hyperscale data center platforms

-

PCIe switch based architectures

-

Hybrid SAS and PCIe storage systems

-

Space constrained compute nodes and workstations

In each case, the interface helps balance performance, density, and manageability.

FAQ (Frequently Asked Questions)

Are SlimSAS cables only used for NVMe storage?

No. They can also support SAS and SATA devices depending on the controller and system design.

Do SlimSAS cables replace all legacy internal connectors?

Not entirely, but they are increasingly preferred in new high density designs.

Is SlimSAS suitable for hot swap applications?

Hot swap capability depends on the backplane and system architecture rather than the cable itself.

Are SlimSAS cables limited in length?

They are intended for short reach internal connections and must be selected within recommended length limits to maintain signal integrity.